Exploring the Relationship Between Glass Coating Lines and Product Innovation

Time:

2025-09-21 09:10

Exploring the Relationship Between Glass Coating Lines and Product Innovation

Table of Contents

- 1. Introduction to Glass Coating Lines

- 2. The Importance of Glass Coating in Modern Manufacturing

- 3. Technological Advancements in Glass Coating Lines

- 4. Driving Product Innovation through Glass Coating

- 5. The Role of Sustainability in Glass Coating Innovations

- 6. Challenges in Implementing Advanced Glass Coating Lines

- 7. Future Trends in Glass Coating Technology

- 8. Conclusion

- 9. FAQs

1. Introduction to Glass Coating Lines

Glass coating lines are integral to the manufacturing process of numerous products, providing a protective and aesthetic finish to glass surfaces. These lines utilize advanced technology to apply coatings that enhance durability, functionality, and visual appeal. As industries evolve, the demand for innovative solutions in glass coatings has surged, pushing manufacturers to explore the intricate relationship between glass coating lines and product innovation.

2. The Importance of Glass Coating in Modern Manufacturing

In today's competitive market, **glass coatings** have become essential for enhancing product attributes. They serve various purposes, including:

2.1 Protection from Environmental Factors

Glass coatings shield surfaces from UV rays, moisture, and mechanical abrasion. This protective layer extends the product's lifespan, ensuring that items such as windows and glass containers remain functional and visually appealing over time.

2.2 Enhancing Aesthetic Appeal

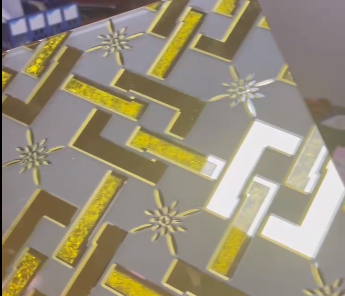

The application of coatings not only protects but also enhances the visual properties of glass. Coatings can provide various finishes, such as glossy or matte, and can be colored or clear, allowing for customization that meets customer preferences.

2.3 Improving Product Performance

Advanced glass coatings can improve thermal insulation and energy efficiency in applications like architectural glass. This functionality aligns with the growing focus on sustainability and energy conservation in manufacturing and construction.

3. Technological Advancements in Glass Coating Lines

Recent innovations in coating technology have transformed how manufacturers apply glass coatings. Key advancements include:

3.1 Automated Coating Processes

Automation in glass coating lines has streamlined production, reducing labor costs and improving consistency. **Robotic systems** can apply coatings with precision, ensuring uniform thickness and minimizing waste.

3.2 Nanotechnology in Coatings

The integration of nanotechnology has led to the development of next-generation coatings that offer superior performance. Nanostructured coatings can provide enhanced scratch resistance, anti-fog properties, and self-cleaning capabilities.

3.3 Smart Coating Technologies

Innovative smart coatings are being developed to respond to environmental stimuli. For instance, coatings that change color based on temperature or light conditions can add unique features to products, opening new avenues for design and functionality.

4. Driving Product Innovation through Glass Coating

The interplay between glass coating lines and product innovation is profound. By utilizing advanced coating technologies, manufacturers can create products that stand out in a crowded marketplace.

4.1 Customization and Personalization

Modern consumers demand products that reflect their personal style. Glass coating lines enable manufacturers to offer customizable options, whether through color selection, texture, or functional enhancements. This flexibility drives customer engagement and satisfaction.

4.2 Development of Multi-functional Products

Glass coatings can imbue products with multiple functionalities. For example, coatings can provide both UV protection and anti-reflective properties in sunglasses, enhancing their usability and appeal.

4.3 Innovative Applications

As industries evolve, new applications for glass coatings continue to emerge. From automotive to electronics, the versatility of glass coatings allows manufacturers to explore innovative solutions that meet specific market needs.

5. The Role of Sustainability in Glass Coating Innovations

Sustainability is a crucial aspect of modern manufacturing processes. Glass coating lines contribute to eco-friendly practices in several ways:

5.1 Reduced Material Waste

Advanced glass coating technologies minimize material waste by optimizing the coating process. Automated systems ensure precise application, reducing overspray and excess usage.

5.2 Eco-friendly Coating Materials

Many manufacturers are now using environmentally friendly materials in their coatings. Water-based and low-VOC (volatile organic compounds) coatings reduce harmful emissions, aligning with global sustainability initiatives.

5.3 Energy-efficient Manufacturing Processes

Innovative technologies in glass coating lines not only improve product performance but also enhance energy efficiency during production. This dual benefit supports sustainable manufacturing goals.

6. Challenges in Implementing Advanced Glass Coating Lines

While the advantages of advanced glass coating lines are clear, challenges remain in their implementation:

6.1 High Initial Investment

Upgrading to advanced coating lines often requires a significant financial commitment. Manufacturers must weigh the long-term benefits against the initial costs to ensure a viable return on investment.

6.2 Technical Expertise Requirements

The complexity of advanced coating technologies demands skilled personnel for operation and maintenance. Companies may face challenges in recruiting and retaining employees with the necessary expertise.

6.3 Supply Chain Considerations

The sourcing of advanced materials and components for glass coating lines can pose logistical challenges. Manufacturers need to establish reliable supply chains to ensure consistent production.

7. Future Trends in Glass Coating Technology

Looking ahead, several trends are set to shape the future of glass coating lines:

7.1 Increased Focus on Smart Technologies

As technology advances, smart coatings that respond to environmental changes will become more prevalent. This trend will likely drive innovation in product design and functionality.

7.2 Growth in Sustainable Practices

The move towards sustainability will continue, with manufacturers investing in eco-friendly coating solutions and processes that reduce environmental impact.

7.3 Enhanced Customization Options

As consumers demand more personalized products, manufacturers will increasingly adopt flexible coating technologies that allow for rapid customization and shorter production runs.

8. Conclusion

The relationship between glass coating lines and product innovation is crucial in modern manufacturing. As industries evolve and consumer demands shift, the need for advanced glass coatings will continue to grow. By embracing technological advancements, sustainability practices, and customization options, manufacturers can enhance their product offerings and maintain a competitive edge in the marketplace. The future of glass coating lines is bright, promising innovations that will redefine product capabilities and consumer experiences.

9. FAQs

Q1: What are glass coating lines, and how do they work?

A1: Glass coating lines are automated systems that apply protective and aesthetic coatings to glass surfaces. The process typically involves cleaning the glass, applying the coating, and curing it to ensure durability.

Q2: What benefits do glass coatings provide?

A2: Glass coatings offer several benefits, including protection from UV rays and moisture, enhanced aesthetic appeal, improved product performance, and increased durability.

Q3: How do technological advancements impact glass coating lines?

A3: Technological advancements, such as automation and nanotechnology, improve the efficiency, precision, and functionality of glass coating lines, enabling manufacturers to produce high-quality coatings more effectively.

Q4: What role does sustainability play in glass coating innovations?

A4: Sustainability is increasingly important in glass coating innovations. Manufacturers are adopting eco-friendly materials and energy-efficient processes to reduce their environmental impact while meeting consumer demands for sustainable products.

Q5: What challenges do manufacturers face when implementing advanced glass coating lines?

A5: Manufacturers may encounter challenges such as high initial investment costs, the need for skilled technical personnel, and potential supply chain issues when upgrading to advanced glass coating lines.

glass coating line

News