Product

Contact

Wechat: +86-198 7884 1913

Product

DZL-High vacuum winding and coating equipment

Glass upper and lower plate table

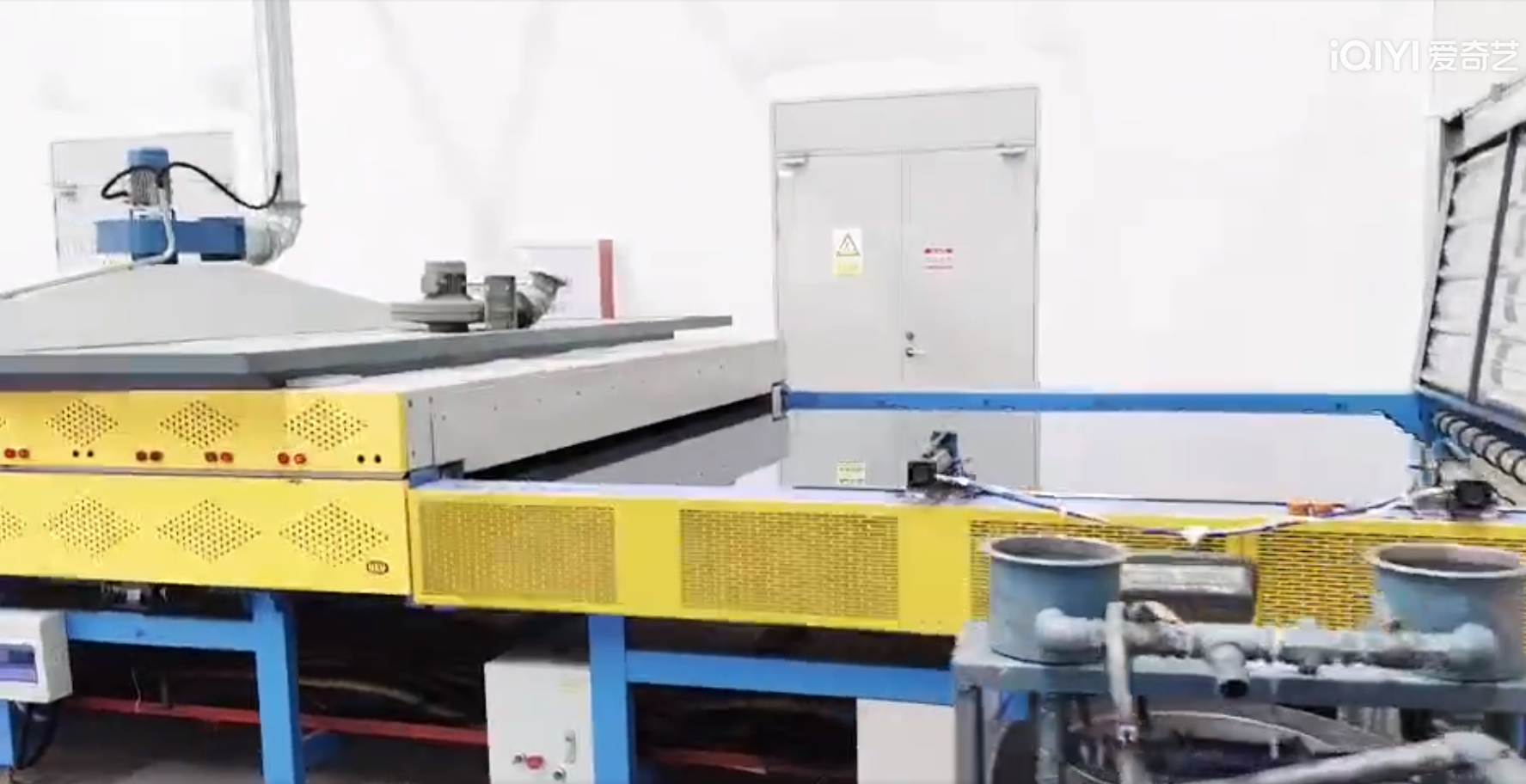

High-end aluminum mirror roller coating UV paint coating production line

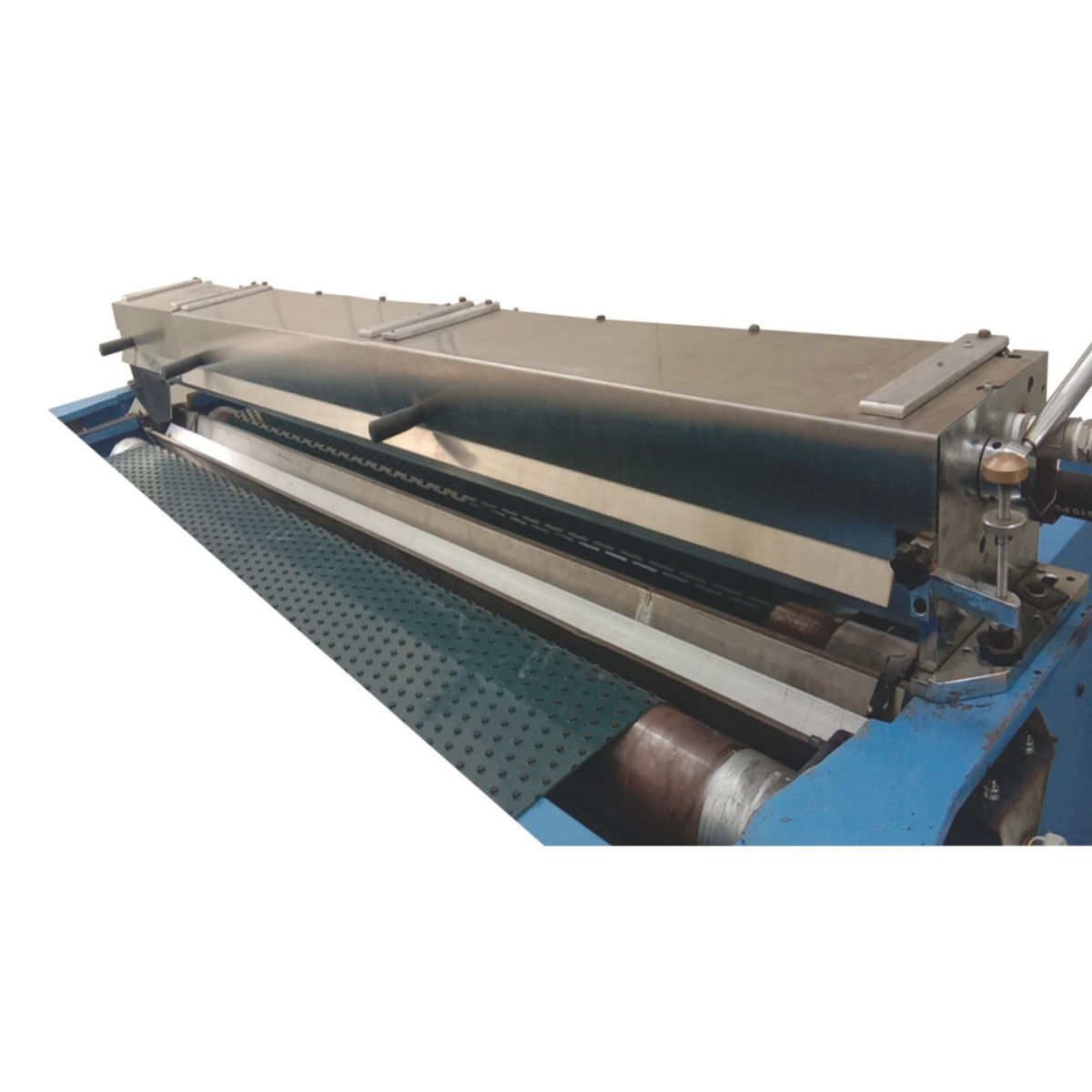

DGT- Energy saving roller coating machine

DAR- SOLAR photovoltaic glass AR film coating production line

DUV- Environmental protection UV curing machine

DJW-Magnetron sputtering glass coating production line

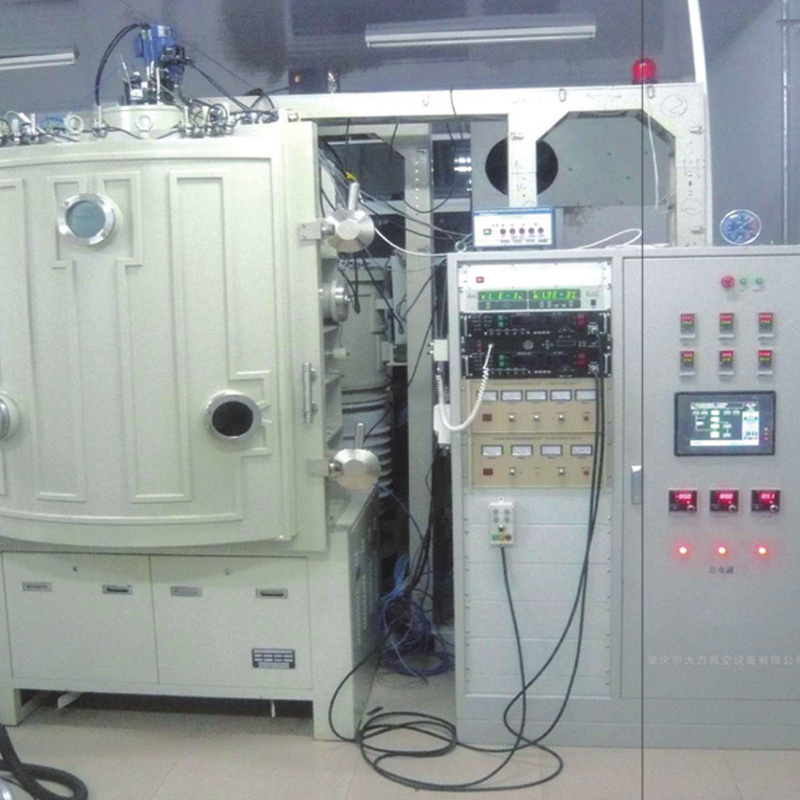

DZ- Vertical vacuum coating machine

High Grade Mirror Silvering Production Line