Evaluating the Effectiveness of Your Glass Coating Line: A Comprehensive Guide

Time:

2025-08-16 12:00

Evaluating the Effectiveness of Your Glass Coating Line

Table of Contents

- Introduction to Glass Coating Lines

- The Importance of Efficient Glass Coating Lines

- Key Metrics for Evaluating Effectiveness

- Common Challenges in Glass Coating Lines

- Strategies for Optimization

- The Role of Technology in Enhancing Performance

- Case Studies: Successful Implementations

- Frequently Asked Questions

- Conclusion

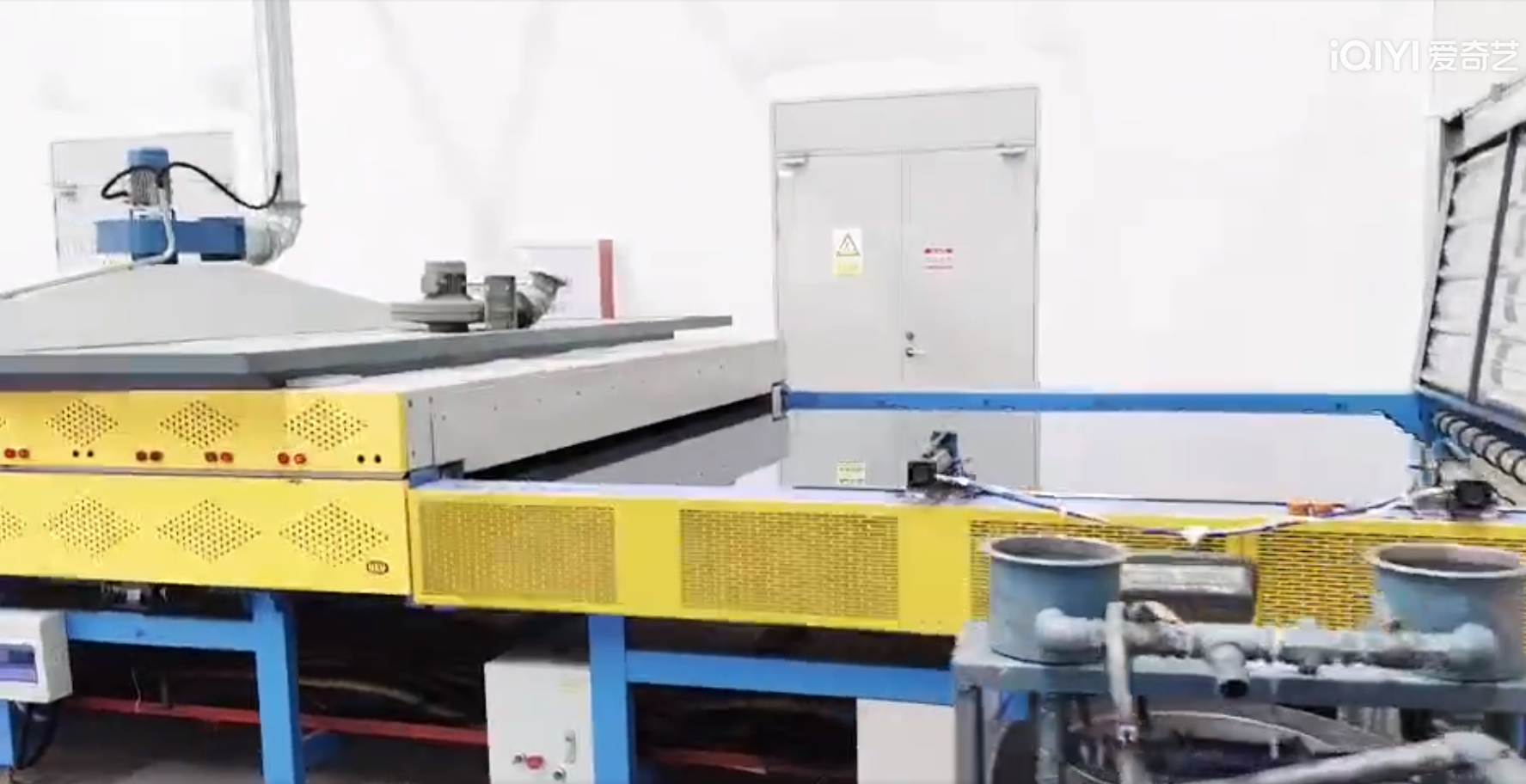

Introduction to Glass Coating Lines

The glass coating industry is evolving rapidly, driven by advancements in technology and increasing demand for high-quality finishes. Efficient glass coating lines are vital for manufacturers aiming to meet stringent quality standards while maximizing productivity. In this comprehensive guide, we explore the factors influencing the effectiveness of glass coating lines, offering insights that can significantly enhance your production processes.

The Importance of Efficient Glass Coating Lines

**Efficiency** in glass coating lines is not merely about speed; it's about achieving a balance between productivity and quality. An effective coating line can lead to:

- **Reduced Waste:** Lower material costs and improved profit margins.

- **Higher Quality Output:** Enhanced customer satisfaction through superior products.

- **Faster Turnaround Times:** Meeting tight deadlines and improving market competitiveness.

- **Sustainability:** Lower energy consumption and reduced environmental impact.

Understanding the importance of these factors is crucial for businesses that aim to thrive in a competitive landscape.

Key Metrics for Evaluating Effectiveness

To measure the effectiveness of your glass coating line, several key metrics should be closely monitored:

1. Production Rate

The **production rate** refers to the quantity of glass coated within a specific timeframe. High production rates indicate an efficient operation but should not compromise quality.

2. Coating Thickness Consistency

Consistency in **coating thickness** is vital for performance. Variability can lead to defects, impacting the overall quality of the end product. Regular monitoring ensures adherence to specifications.

3. Adhesion Quality

The **adhesion quality** of the coating directly influences the durability and functionality of the glass. Conducting adhesion tests helps in assessing the effectiveness of the coating process.

4. Downtime Analysis

Minimizing **downtime** is crucial for maximizing efficiency. Regular maintenance schedules and quick troubleshooting protocols can reduce production interruptions.

5. Energy Consumption

Monitoring **energy consumption** helps in identifying areas for improvement. High energy usage may indicate inefficiencies in equipment or processes.

6. User Feedback

Feedback from operators and quality control teams provides valuable insights into the effectiveness of the coating line. Their experiences can reveal underlying issues that may not be evident through data alone.

Common Challenges in Glass Coating Lines

Despite the advancements in technology, several challenges persist in glass coating operations:

1. Equipment Reliability

**Equipment failures** can lead to significant production losses. Regular maintenance and timely upgrades are essential to ensure reliability.

2. Environmental Factors

Variability in **environmental conditions**, such as humidity and temperature, can affect coating quality. Implementing climate control measures can mitigate these impacts.

3. Material Compatibility

Choosing the right **coating materials** that are compatible with various glass types is critical. Incompatibilities can result in adhesion issues and product failures.

4. Compliance with Standards

Manufacturers must comply with local and international **quality standards**. Regular audits and assessments ensure adherence to these regulations.

Strategies for Optimization

To overcome challenges and enhance the effectiveness of your glass coating line, consider implementing the following strategies:

1. Invest in Training

Comprehensive training programs for operators can improve efficiency and quality. Skilled personnel can identify potential issues early and implement corrective actions.

2. Embrace Automation

Integrating **automation technologies** can streamline processes, reduce human error, and enhance consistency. Automated systems can also improve data collection for performance analysis.

3. Regular Maintenance and Upgrades

Implementing a robust maintenance schedule helps in preventing unexpected breakdowns. Investing in new technologies can also enhance production capabilities.

4. Process Optimization

Continual assessment and optimization of coating processes can lead to significant improvements. Techniques such as lean manufacturing can reduce waste and improve efficiency.

5. Quality Control Measures

Establishing strict quality control measures at various stages of production ensures that products meet the required standards. Continuous monitoring can help in maintaining high-quality outputs.

The Role of Technology in Enhancing Performance

Modern technologies play a significant role in improving the effectiveness of glass coating lines:

1. Advanced Coating Technologies

Innovations in coating technology, such as nano-coatings, improve durability and performance. These advanced coatings offer better resistance to scratches, chemical exposure, and environmental factors.

2. Data Analytics

Utilizing data analytics tools can provide insights into performance metrics, enabling manufacturers to make informed decisions regarding process improvements.

3. IoT Integration

Integrating the Internet of Things (IoT) can facilitate real-time monitoring of systems, allowing for quick identification of issues and optimization of processes.

4. Robotic Process Automation

Using robots for tasks such as loading and unloading can reduce physical strain on workers and improve speed and accuracy in production.

Case Studies: Successful Implementations

To illustrate the impact of effective evaluation and optimization, we examine a few case studies from leading manufacturers in the glass coating industry.

Case Study 1: Manufacturer A

Manufacturer A implemented a comprehensive training program for its operators, resulting in a 20% increase in production efficiency. By focusing on quality control, they reduced defects by 30%.

Case Study 2: Manufacturer B

By investing in automated systems, Manufacturer B reduced its downtime by 40%. The integration of IoT solutions allowed for real-time monitoring, leading to quicker response times for any issues that arose.

Case Study 3: Manufacturer C

Manufacturer C focused on process optimization, leading to an overall reduction in energy consumption by 25%. They implemented lean practices, resulting in reduced waste and improved profitability.

Frequently Asked Questions

1. What is the ideal production rate for glass coating lines?

The ideal production rate varies depending on the specific application and equipment. It is essential to balance speed with quality to ensure optimal outcomes.

2. How can I improve coating adhesion on glass?

Improving adhesion can be achieved by ensuring surface cleanliness, selecting compatible coating materials, and optimizing application techniques.

3. What role does temperature play in the coating process?

Temperature significantly affects coating viscosity and drying times. Maintaining optimal temperature conditions is crucial for achieving desired quality.

4. How often should maintenance be performed on coating equipment?

Regular maintenance schedules should be established based on equipment usage and manufacturer recommendations, typically ranging from monthly to quarterly checks.

5. What are the benefits of using automated systems in glass coating?

Automated systems enhance productivity, reduce labor costs, improve consistency, and minimize human error, ultimately leading to better quality products.

Conclusion

Evaluating the effectiveness of your glass coating line is a multifaceted process that requires attention to various metrics, challenges, and optimization strategies. By closely monitoring production rates, coating quality, and implementing advanced technologies, manufacturers can significantly enhance their operations. Embracing a culture of continuous improvement will not only lead to increased efficiency but also to higher customer satisfaction and profitability. By following the insights and strategies outlined in this guide, manufacturers can position themselves as leaders in the glass coating industry, prepared to meet the demands of an ever-evolving market.

glass coating line

Previous

News