Essential Tools for Maintaining Your Glass Coating Line: A Comprehensive Guide

Time:

2025-07-11 09:40

Essential Tools for Maintaining Your Glass Coating Line

Maintaining a glass coating line requires a thorough understanding of both the equipment and the processes involved. The glass coating line is crucial for enhancing the properties of glass, including durability, scratch resistance, and aesthetic appeal. Proper maintenance ensures that the line operates efficiently, reducing downtime and improving product quality. Here, we delve into the essential tools and techniques for maintaining your glass coating line, helping you achieve optimal performance.

Table of Contents

- Introduction to Glass Coating Lines

- The Importance of Regular Maintenance

- Key Tools for Effective Maintenance

- Cleaning Equipment: Keeping Your Line Pristine

- Calibration Tools: Ensuring Accuracy

- Monitoring Systems: Tracking Performance

- Troubleshooting Common Issues

- Expert Tips for Optimal Performance

- Frequently Asked Questions

- Conclusion

Introduction to Glass Coating Lines

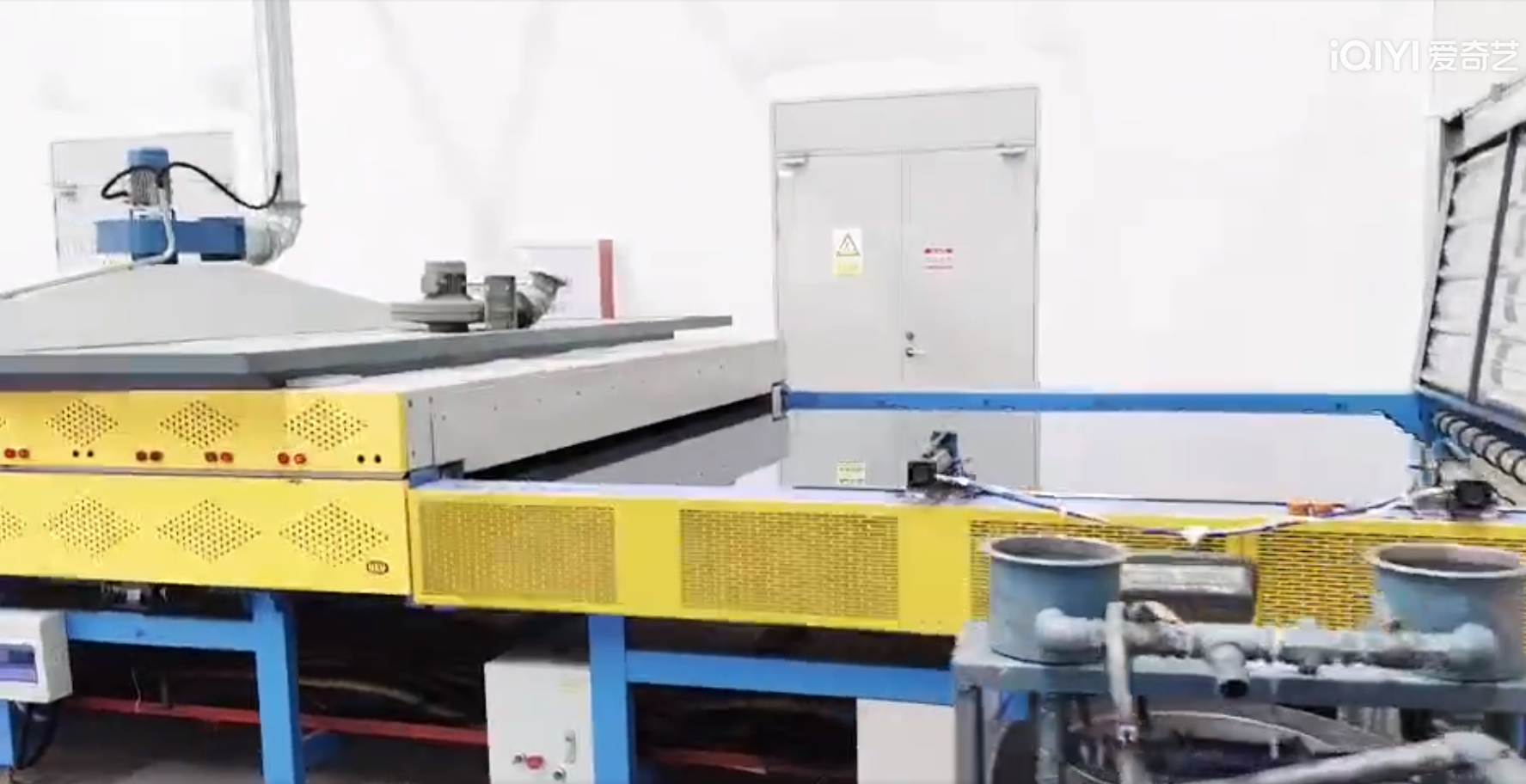

Glass coating lines are instrumental in industries ranging from construction to automotive. These lines apply various coatings to glass surfaces, enhancing their performance and longevity. Understanding the machinery and processes involved is essential for maintaining high-quality output. The components of a glass coating line typically include pre-treatment systems, coating applicators, curing units, and cooling systems.

The Importance of Regular Maintenance

Regular maintenance of glass coating lines is crucial for several reasons:

1. **Prevention of Downtime**: Scheduled maintenance reduces the likelihood of unexpected breakdowns, which can halt production and lead to significant financial losses.

2. **Enhanced Product Quality**: A well-maintained coating line ensures uniform application and curing of coatings, resulting in higher quality glass products.

3. **Extended Equipment Life**: Regularly servicing machinery helps prevent wear and tear, extending the lifespan of critical components.

4. **Safety Compliance**: Adhering to maintenance schedules ensures that all safety standards are met, protecting employees and equipment.

Key Tools for Effective Maintenance

To ensure the longevity and efficiency of your glass coating line, a variety of specialized maintenance tools are essential. These tools can be categorized into several types based on their function.

Cleaning Tools

Pressure Washers

Pressure washers are fundamental for cleaning the exterior surfaces of the coating line. They help in removing dust, grime, and residues that can interfere with operations.

Brushes and Scrapers

Detail brushes and scrapers are necessary for maintaining smaller components and hard-to-reach areas within the machinery.

Diagnostic Tools

Multimeters

Multimeters are essential for diagnosing electrical issues within the machinery. They measure voltage, current, and resistance, ensuring that all electrical components function correctly.

Infrared Thermometers

Infrared thermometers are useful for monitoring temperature at various points in the coating line, especially in curing processes to ensure optimal conditions.

Calibration Tools

Calibration Gauges

Calibration gauges are vital for ensuring that all measurement systems, including thickness gauges and pressure gauges, are accurate and reliable.

Laser Alignment Tools

These tools help maintain precise alignment of moving parts, which is critical for the proper operation of the coating line.

Monitoring Systems

Real-time Monitoring Software

Implementing real-time monitoring software can help track the performance of the coating line, allowing for quick identification of issues.

Data Logging Devices

Data loggers keep track of various parameters over time, facilitating detailed analysis and trend identification for proactive maintenance.

Troubleshooting Common Issues

Even with the best maintenance practices, issues can arise. Here are some common problems encountered in glass coating lines and how to troubleshoot them:

Inconsistent Coating Application

This issue can stem from several factors, including improper calibration of applicators or contamination in the coating material. Ensure that all applicators are regularly calibrated and that the coating materials are clean and free from particulates.

Bubbling or Peeling Coatings

Bubbling or peeling typically indicates inadequate curing. Verify that the curing unit is functioning correctly and that the temperature settings are appropriate for the specific coating being used.

Unusual Equipment Noise

If machinery produces strange noises, it may indicate wear in bearings or misalignment. Conduct a thorough inspection of moving parts and lubricate as necessary.

Expert Tips for Optimal Performance

1. **Maintain a Routine Schedule**: Establish a maintenance schedule that includes daily, weekly, and monthly tasks. Routine inspections can catch potential issues before they escalate.

2. **Train Your Team**: Ensure that all operators are trained on proper maintenance procedures. Knowledgeable staff can recognize problems early on, preventing costly repairs.

3. **Document Everything**: Keep detailed records of maintenance activities, repairs, and inspections. This data can be invaluable for identifying trends and making informed decisions about upgrades or replacements.

4. **Invest in Quality Tools**: Ensure that you are using high-quality tools for maintenance. Investing in durable and reliable equipment will pay off in the long run.

5. **Stay Updated with Technology**: Keep abreast of advancements in coating technologies and maintenance practices. New tools and techniques can significantly enhance the efficiency and effectiveness of your maintenance efforts.

Frequently Asked Questions

1. How often should I perform maintenance on my glass coating line?

We recommend establishing a routine maintenance schedule based on the manufacturer’s guidelines and production levels. Typically, daily checks followed by weekly and monthly in-depth inspections are beneficial.

2. What are the signs that my glass coating line needs maintenance?

Look for signs such as inconsistent coating quality, unusual noises, equipment overheating, or frequent breakdowns. These indicators suggest that a maintenance check is necessary.

3. Can I perform maintenance on my glass coating line myself?

While some maintenance tasks can be performed in-house, it is advisable to consult with professionals for complex repairs or calibrations to ensure proper handling and safety.

4. What are the most common causes of coating defects?

Common causes include contamination of the coating material, improper curing temperatures, and equipment misalignment. Regular maintenance can help mitigate these issues.

5. How can I improve the efficiency of my glass coating line?

Improving efficiency can be achieved by regular maintenance, upgrading to more efficient equipment, and implementing real-time monitoring systems for better performance tracking.

Conclusion

Maintaining your glass coating line is not just about keeping equipment running; it’s about ensuring quality and efficiency throughout the production process. By employing the right tools, adhering to a regular maintenance schedule, and staying informed about best practices, you can significantly enhance the performance of your glass coating line. With the insights provided in this article, you are now equipped to maintain your coating line effectively, ensuring long-term success in your operations.

glass coating line

Previous

News