Maximizing Efficiency and Quality in Glass Coating Lines

Time:

2025-04-27 10:20

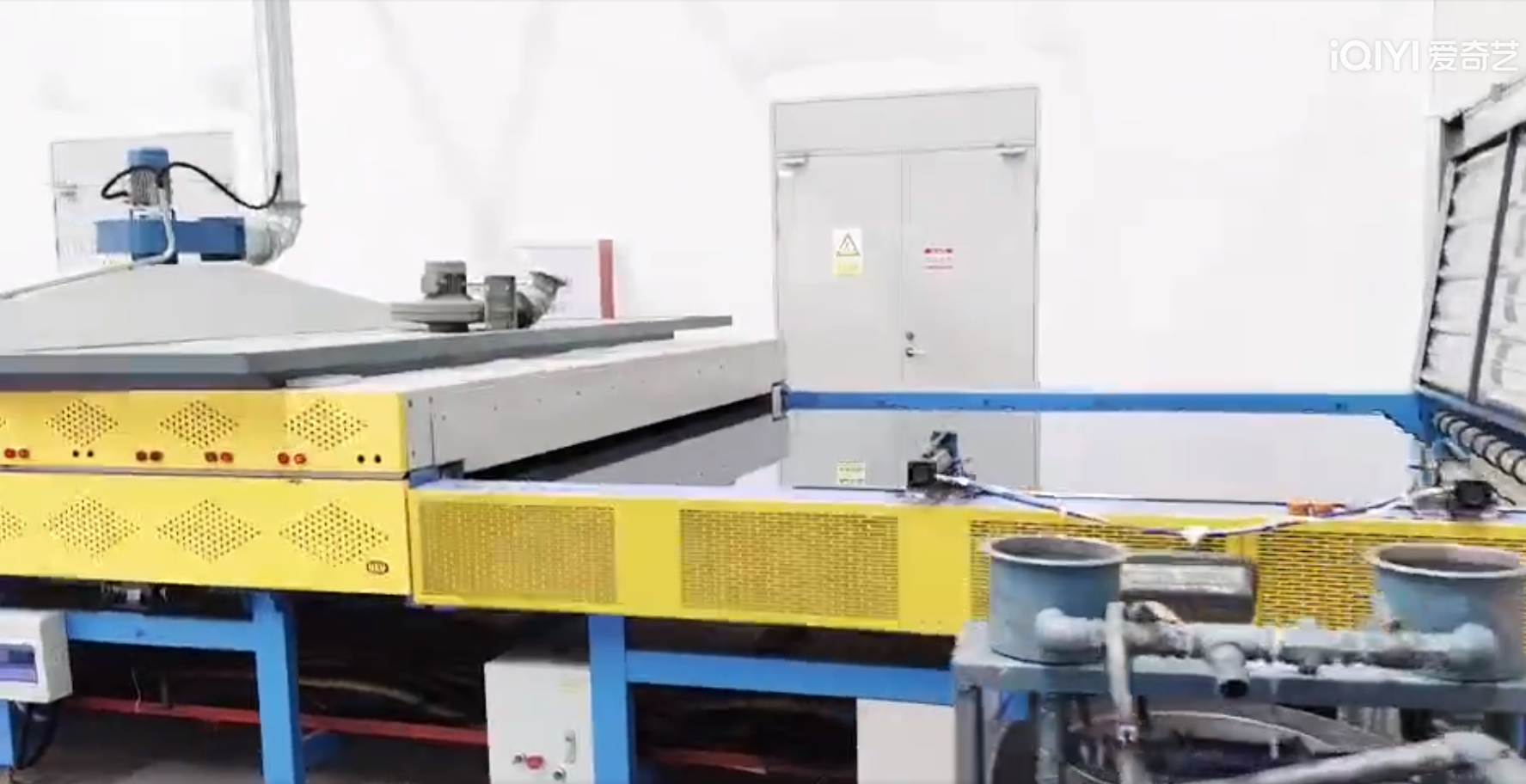

In the competitive landscape of industrial equipment and components, particularly within the coating equipment sector, enhancing the efficiency and quality of glass coating lines is crucial for gaining a competitive edge. A glass coating line is designed primarily for applying protective and decorative coatings to glass surfaces, making it essential for various industries, including automotive, construction, and electronics.

One of the primary considerations when analyzing glass coating lines is the choice of technology. Advanced technologies such as vacuum deposition and spray coating can significantly improve the precision and uniformity of coatings. Vacuum deposition, for example, allows for the application of ultra-thin coatings that provide enhanced durability and optical clarity. Understanding the specific requirements of your production needs can guide the selection of the right technology for your glass coating line.

Another vital aspect is the integration of automation within the glass coating line. Automated systems can streamline processes, reduce labor costs, and minimize human error. Incorporating robotics for tasks such as loading and unloading, monitoring coating thickness, and quality assurance can greatly enhance operational efficiency. Furthermore, utilizing real-time data analytics can help in monitoring the performance of the coating process, enabling adjustments on the fly to maintain high-quality standards.

Environmental considerations are also increasingly important in the design and operation of glass coating lines. Implementing sustainable practices, such as recycling solvents and using water-based coatings, can not only comply with regulations but also appeal to environmentally conscious consumers. The use of energy-efficient machinery can further reduce the carbon footprint of your operations.

Training and workforce development is another critical area. Investing in training programs for your employees ensures that they are equipped with the necessary skills to operate complex machinery and understand the nuances of coating applications. A knowledgeable workforce can lead to fewer errors and higher product quality, thereby enhancing overall production effectiveness.

Lastly, regular maintenance and upgrades of your glass coating line cannot be overlooked. Keeping your equipment in optimal condition extends its lifespan and maintains the quality of the coatings applied. It is advisable to establish a routine maintenance schedule and stay informed about the latest advancements in coating technologies to ensure your production line remains competitive.

In conclusion, optimizing glass coating lines involves a multifaceted approach that includes technology selection, automation, sustainability, workforce training, and maintenance. By focusing on these areas, businesses in the industrial equipment and components sector can enhance both efficiency and quality, ensuring they meet the evolving demands of their customers.

One of the primary considerations when analyzing glass coating lines is the choice of technology. Advanced technologies such as vacuum deposition and spray coating can significantly improve the precision and uniformity of coatings. Vacuum deposition, for example, allows for the application of ultra-thin coatings that provide enhanced durability and optical clarity. Understanding the specific requirements of your production needs can guide the selection of the right technology for your glass coating line.

Another vital aspect is the integration of automation within the glass coating line. Automated systems can streamline processes, reduce labor costs, and minimize human error. Incorporating robotics for tasks such as loading and unloading, monitoring coating thickness, and quality assurance can greatly enhance operational efficiency. Furthermore, utilizing real-time data analytics can help in monitoring the performance of the coating process, enabling adjustments on the fly to maintain high-quality standards.

Environmental considerations are also increasingly important in the design and operation of glass coating lines. Implementing sustainable practices, such as recycling solvents and using water-based coatings, can not only comply with regulations but also appeal to environmentally conscious consumers. The use of energy-efficient machinery can further reduce the carbon footprint of your operations.

Training and workforce development is another critical area. Investing in training programs for your employees ensures that they are equipped with the necessary skills to operate complex machinery and understand the nuances of coating applications. A knowledgeable workforce can lead to fewer errors and higher product quality, thereby enhancing overall production effectiveness.

Lastly, regular maintenance and upgrades of your glass coating line cannot be overlooked. Keeping your equipment in optimal condition extends its lifespan and maintains the quality of the coatings applied. It is advisable to establish a routine maintenance schedule and stay informed about the latest advancements in coating technologies to ensure your production line remains competitive.

In conclusion, optimizing glass coating lines involves a multifaceted approach that includes technology selection, automation, sustainability, workforce training, and maintenance. By focusing on these areas, businesses in the industrial equipment and components sector can enhance both efficiency and quality, ensuring they meet the evolving demands of their customers.

glass coating line

News